Welcome Here Shenzhen Mingjiada Electronics Co., Ltd.

sales@hkmjd.com

sales@hkmjd.com

Service Telephone:86-755-83294757

Latest Information

Latest Information Home

/Industry Information

/

Home

/Industry Information

/

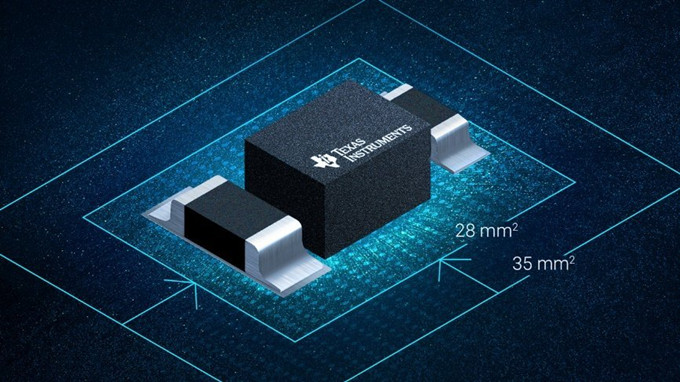

50% smaller, MagPack magnetic packaging technology reshapes power module

Texas Instruments (TI) has introduced six new power modules designed to increase power density, improve efficiency and reduce EMI. Using Texas Instruments proprietary MagPack integrated magnetic packaging technology, these power modules are up to 23 p…

Texas Instruments (TI) has introduced six new power modules designed to increase power density, improve efficiency and reduce EMI. Using Texas Instruments' proprietary MagPack integrated magnetic packaging technology, these power modules are up to 23 percent smaller than comparable products on the market, enabling designers in industrial, enterprise and communications applications to achieve higher levels of performance.

In particular, three of the six new devices (TPSM82866A, TPSM82866C and TPSM82816) are subminiature 6A power modules that can provide current output capacity of 1A per square millimeter. This performance is undoubtedly remarkable, especially considering that the 0603 component takes up 1.28mm2 of board space.

If users require additional features such as adjustable soft start, adjustable switching frequency, clock synchronization and adjustable control loop compensation, the PSU scheme based on the TPSM82816 will increase in size from 28mm2 to 46mm2 in the standard version and provide A current power density of 0.8A/mm, which is still very small for a 6A power supply.

As we all know, the power module by integrating the power chip and passive devices, such as inductors, capacitors, in a single package to save valuable space, how to efficiently provide more power in a smaller space, is always the challenge faced by power design engineers. Yao Yunruo, product line manager of Texas Instruments' booster - booster switch regulator, also stressed that if they can improve the power module through innovative packaging technology, save valuable printed circuit board (PCB) layout space, and provide excellent power density, efficiency and thermal performance, it will be very exciting news for them.

The key to the size reduction comes from MagPack packaging technology, which uses Texas Instruments' unique 3D packaging molding process to minimize the height, width and depth of the power module to deliver more output power in a smaller space.

According to reports, the magnetic packaging technology uses an integrated power inductor made of a proprietary new design material. By using this type of power module, engineers can more easily obtain high power density, low temperature, low EMI radiation, high conversion efficiency of the power system design. Some analysts predict that data center power demand will increase by 100 percent by 2030. The above performance advantages brought by power modules can play an important role in applications such as data centers to improve power efficiency.

In addition, high efficiency and good thermal performance are the second characteristics of MagPack packaging technology. Because after reducing the size and increasing the power density, the heat in the smaller package must be removed immediately and effectively, and the reliable operation of the power module must be maintained. So MagPack technology uses inductors that are matched to silicon chips to reduce DC and AC losses. Pairing these two circuit elements with a high-performance, highly conductive MagPack package helps effectively remove heat from the power module.

A third benefit is that devices using MagPack technology have integrated inductors. As the most difficult component to select and procure in a power supply design, considering its size, height, and interference with other circuits, inductors are often one of the most difficult components to place and route on a PCB. Power modules with integrated inductors eliminate these issues, while inductors used in MagPack technology alleviate these challenges.

MagPack technology provides high efficiency and excellent thermal performance, but also alleviates another problem of all power supply designs: electromagnetic interference (EMI). Power module technology with MagPack is shielded, which is not just a shielded inductor, but the entire chip, inductor, switch node - all packaged in a shielded package. In addition, the size of power modules with MagPack technology and the optimized wiring inside the package make the wiring of noisy signals in the power module and system shorter and smaller. The data show that the radiation EMI is reduced by up to 8dB.

Article source: Electronic Engineering Album

Company website www.hkmjd.com

Time:2025-08-19

Time:2025-08-19

![Mingjiada Supply [ADI] LT3502AEDC 500mA, Step-Down DC/DC Regulators](/upload/202508/19/202508191511211474.jpg)

Time:2025-08-19

Time:2025-08-19

Contact Number:86-755-83294757

Enterprise QQ:1668527835/ 2850151598/ 2850151584/ 2850151585

Business Hours:9:00-18:00

E-mail:sales@hkmjd.com

Company Address:Room1239, Guoli building, Zhenzhong Road, Futian District, Shenzhen, Guangdong

CopyRight ©2022 Copyright belongs to Mingjiada Yue ICP Bei No. 05062024-12

Official QR Code

Links: