Welcome Here Shenzhen Mingjiada Electronics Co., Ltd.

sales@hkmjd.com

sales@hkmjd.com

Service Telephone:86-755-83294757

Latest Information

Latest InformationToshiba Electronic Devices & Storage Corporation (Toshiba) today announced the launch of the TLX9161T, an automotive optical relay[1] in a compact SO12L-T package. The product has a minimum output voltage withstand of 1500V, meeting the requiremen…

Toshiba Electronic Devices & Storage Corporation (Toshiba) today announced the launch of the TLX9161T, an automotive optical relay[1] in a compact SO12L-T package. The product has a minimum output voltage withstand of 1500V, meeting the requirements of high-voltage automotive battery applications. Mass shipments of the new product will begin today.

Shorter charging times and longer driving ranges are critical to the widespread adoption of electric vehicles, and the key to addressing these issues lies in the more efficient operation of battery systems. The Battery Management System (BMS) monitors the battery's charging status to ensure system efficiency, while also monitoring insulation between the battery and the vehicle body to ensure safe use of high-voltage batteries. Additionally, the BMS employs electrically isolated optical relays to handle high voltages.

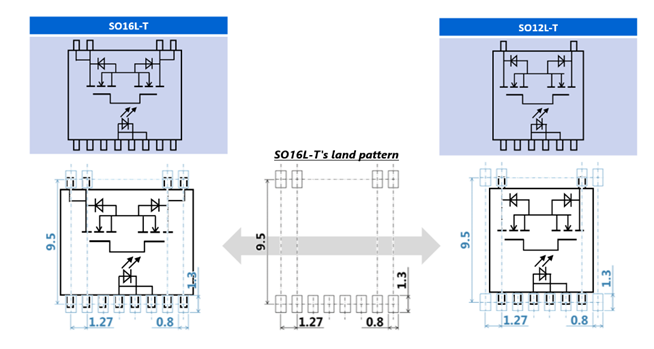

Toshiba's new product is a high-voltage optocoupler with an output voltage rating of 1500V (minimum), representing a miniaturised version of the Toshiba TLX9160T optocoupler. By miniaturising the size of the built-in MOSFET chip, the product achieves an SO12L-T package, with a mounting area approximately 25% smaller than the SO16L-T package of the TLX9160T [2]. Additionally, this size reduction contributes to the miniaturisation and cost reduction of battery management systems. The pin pitch and pin layout are identical to those of the SO16L-T (Figure 1), allowing for the use of the same pad size design.

Figure 1: Pin allocation and pad layout of SO16L-T and SO12L-T

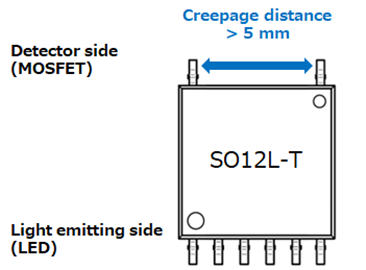

The new optical relay uses a resin with a relative tracking index (CTI[3]) exceeding 600, classified as Class I material[4] under the IEC 60664-1[5] international standard. The pin configuration ensures a creepage distance of over 5mm[6] on the detector side (Figure 2). These characteristics comply with the IEC 60664-1 standard, enabling an operating voltage of 1000V.

Figure 2: Pin configuration of the SO12L-T package

In the future, Toshiba will continue to expand its automotive optical relay product line and provide solutions to address the challenges of the widespread adoption of electric vehicles, contributing to the realisation of a carbon-neutral society.

Applications:

- Automotive equipment: BMS (battery voltage monitoring, mechanical relay sticking detection, ground fault detection, etc.)

- Replacement for mechanical relays

Features:

- Compact package: SO12L-T (7.76mm × 10.0mm × 2.45mm (typical))

- Output voltage rating: VOFF = 1500V (minimum)

- Normally open (1-Form-A) device

- Avalanche current rating: IAV = 0.6mA

- High isolation voltage rating: 5000Vrms (minimum)

- Certified to AEC-Q101

- Compliant with IEC 60664-1 international standard

Notes:

[1] Optical relay: The primary side (control) and secondary side (switch) are electrically isolated. Switches directly connected to AC lines and switches between devices with different ground potentials can be controlled via an insulating layer.

[2] Comparison of SO16L-T package dimensions (10.3mm × 10.0mm × 2.45mm) with SO12L-T package dimensions (7.76mm × 10.0mm × 2.45mm).

[3] Relative tracking index (CTI): An index indicating the voltage withstand capability of insulating materials before electrical tracks (conductive paths) form along their surfaces.

[4] Class I materials: A classification of moulded materials in IEC 60664-1, referring to materials with a relative tracking index (CTI[3]) of 600 or higher.

[5] IEC 60664-1: This standard specifies the principles, requirements, and test methods for insulation coordination in systems with AC voltages up to 1000V or DC voltages up to 1500V.

[6] 5 mm or more: The creepage distance required for a working voltage of 1000 V, Class I material, and pollution level 2 (the degree of pollution in the working environment of electrical equipment: pollutants are completely non-conductive but may become conductive due to condensation).

![Supply [ON] Original Chips: NCV7424DB0R2G Four Channel LIN Transceiver](/upload/202508/22/202508221542263374.jpg)

Time:2025-08-22

Time:2025-08-22

Time:2025-08-22

Time:2025-08-22

Contact Number:86-755-83294757

Enterprise QQ:1668527835/ 2850151598/ 2850151584/ 2850151585

Business Hours:9:00-18:00

E-mail:sales@hkmjd.com

Company Address:Room1239, Guoli building, Zhenzhong Road, Futian District, Shenzhen, Guangdong

CopyRight ©2022 Copyright belongs to Mingjiada Yue ICP Bei No. 05062024-12

Official QR Code

Links: