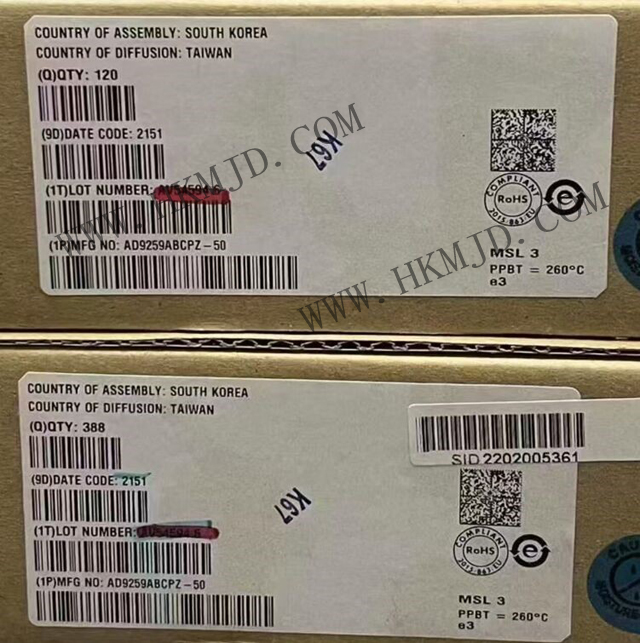

Welcome Here Shenzhen Mingjiada Electronics Co., Ltd.

sales@hkmjd.com

sales@hkmjd.com

Service Telephone:86-755-83294757

Latest Information

Latest Information Home

/Industry Information

/

Home

/Industry Information

/

ON Semiconductor's NCS32100 Leads the Way in Next-Generation Position Sensing Technology

In industrial automation, robotics control, motor drives, and other applications, high-precision position sensors are critical components that directly impact system performance, stability, and cost. Traditional magnetic, optical, and rotary transform…

In industrial automation, robotics control, motor drives, and other applications, high-precision position sensors are critical components that directly impact system performance, stability, and cost. Traditional magnetic, optical, and rotary transformer-based position sensors each have their own advantages and disadvantages. However, inductive position sensors, with their advantages of contamination resistance, vibration resistance, high precision, and low cost, are increasingly becoming the preferred choice for many industrial applications.

Highlighting ON Semiconductor's NCS32100—a groundbreaking dual-inductive rotary position sensor that overcomes the accuracy and speed limitations of traditional inductive sensors, setting a new standard for industrial position sensing.

1. Advantages of Inductive Position Sensors and Selection Criteria

When selecting industrial-grade high-precision position sensors, the following key factors should be considered:

(1) Accuracy and Resolution

Optical encoders typically offer high precision (e.g., ±50 arc seconds) but are sensitive to contamination.

Magnetic encoders are cost-effective but susceptible to interference from stray magnetic fields.

Inductive encoders (such as the NCS32100) provide ±50 arc seconds of precision and are unaffected by environmental conditions.

(2) Interference Resistance

Optical sensors are prone to interference from dust and oil contamination.

Magnetic sensors are susceptible to interference from motor magnetic fields.

Inductive sensors (such as the NCS32100) are insensitive to contaminants, vibrations, and temperature changes, making them suitable for harsh industrial environments.

(3) Speed and Dynamic Performance

Traditional inductive sensors have low speeds (typically <1,000 RPM).

The NCS32100 supports 6,000 RPM at full accuracy, with a maximum of 100,000 RPM (with slightly reduced accuracy).

(4) Integration and Cost

Rotary transformers are large in size and high in cost.

The NCS32100 uses a PCB inductive design, eliminating the need for additional mechanical structures and reducing BOM costs.

2. ON Semiconductor NCS32100: Redefining Inductive Position Sensors

(1) Product Overview

The NCS32100 is ON Semiconductor's dual-inductor rotary position sensor, featuring patented inductive technology that achieves ±50 arcseconds of high precision at 6,000 RPM and supports ultra-high speeds of 100,000 RPM (with reduced accuracy).

(2) Core Features

High Precision: ±50 arc seconds (6,000 RPM), outperforming traditional inductive sensors.

High-Speed Operation: Supports 100,000 RPM (reduced accuracy mode), suitable for industrial robots and servo systems.

Dust and Vibration Resistance: Unaffected by dust, oil contamination, or mechanical vibrations, with reliability far exceeding optical encoders.

Integrated MCU (ARM Cortex-M0+): Built-in firmware supports plug-and-play functionality, reducing development time.

Automatic calibration: Completes calibration in just 2 seconds, adapting to different PCB designs.

Wide voltage supply (2.75V–5.5V): Supports battery backup mode, suitable for critical applications.

(3) Technical Parameters

Accuracy: ±50 arc seconds (6,000 RPM)

Maximum speed: 100,000 RPM (reduced accuracy mode)

Resolution: 20-bit single-turn / 24-bit multi-turn

Interface: UART, SPI, RS-485 (2.5 Mbps)

Supply voltage: 2.75V-5.5V

Operating temperature: -40°C to +125°C

Package: 5mm x 5mm QFN

(4) Typical Applications

Industrial Robots: Collaborative Robots (Cobots), SCARA Robots.

Servo Motor Control: High-Precision Position Feedback.

Automated Guided Vehicles (AGVs): Navigation and Steering Control.

Elevators and Forklifts: Safety Position Detection.

4. Conclusion: NCS32100 — The Future of Industrial Position Sensing

On Semiconductor's NCS32100 leverages innovative inductive sensing technology to address the limitations of traditional inductive sensors in terms of accuracy and speed, making it an ideal choice for high-end applications such as industrial robots, servo motors, and AGVs.

Its high precision (±50 arc seconds), high speed (100,000 RPM), contamination resistance, and automatic calibration features give it a significant advantage in the industrial automation field. For engineers requiring high reliability, ease of use, and cost-effectiveness, the NCS32100 is undoubtedly one of the most competitive inductive position sensors currently available on the market.

Time:2025-08-14

Time:2025-08-14

Time:2025-08-14

Time:2025-08-14

Contact Number:86-755-83294757

Enterprise QQ:1668527835/ 2850151598/ 2850151584/ 2850151585

Business Hours:9:00-18:00

E-mail:sales@hkmjd.com

Company Address:Room1239, Guoli building, Zhenzhong Road, Futian District, Shenzhen, Guangdong

CopyRight ©2022 Copyright belongs to Mingjiada Yue ICP Bei No. 05062024-12

Official QR Code

Links: