Welcome Here Shenzhen Mingjiada Electronics Co., Ltd.

sales@hkmjd.com

sales@hkmjd.com

Service Telephone:86-755-83294757

Latest Information

Latest Information Home

/Industry Information

/

Home

/Industry Information

/

Wolfspeed 1700 V MOSFET Technology Helps Reshape Auxiliary Power Systems

Low-power auxiliary power supplies are found in nearly all motor drives, electric vehicles, fast chargers, and renewable energy systems. Although these power supplies typically receive less attention than the main power stage, they remain a critical c…

Low-power auxiliary power supplies are found in nearly all motor drives, electric vehicles, fast chargers, and renewable energy systems. Although these power supplies typically receive less attention than the main power stage, they remain a critical component in ensuring the efficient operation of the system. Designers are constantly faced with the challenge of improving system reliability, reducing system size and cost, while minimising risk and supporting multi-source procurement—often conflicting objectives.

Wolfspeed’s industrial-grade C3M0900170x and automotive-grade certified (AEC-Q101) E3M0900170x silicon carbide MOSFET product series enhance the design capabilities of auxiliary power supplies across the 20 to 200 W range. These power supplies are becoming increasingly important in rapidly growing markets such as renewable energy, industrial motor control, and vehicle electrification. Based on Wolfspeed's reliable third-generation silicon carbide technology and exclusively manufactured in industry-leading 200 mm fabrication facilities, this product series enables engineers to rethink how to address the various trade-offs in low-power auxiliary power supply system design.

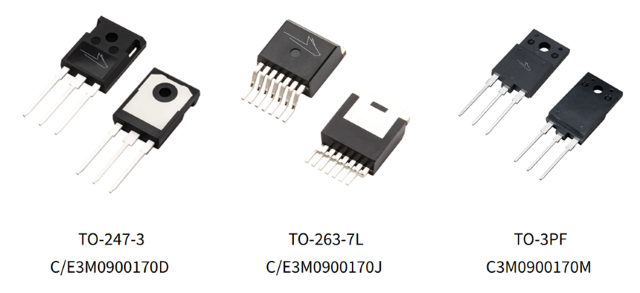

In addition to the TO-247-3 (D) and TO-263-7 (J) packages, the Wolfspeed product portfolio now includes a new fully moulded package, the TO-3PF (M), designed to support industrial applications. This package reduces assembly costs and the risk of errors by eliminating the need for insulating thermal interface materials. Additionally, the TO-3PF (M) package enhances product robustness in harsh environments by increasing the minimum creepage distance between pins to 4.85 mm and eliminating exposed drain plates.

Higher performance and plug-and-play capability

Compared to the previous C2M 1700 V series and competing products, Wolfspeed's C3M and E3M SiC MOSFET technology offers several improvements. In the newly launched C3M/E3M series, gate charge has been reduced from 22 nC in equivalent C2M devices to just 10 nC, reducing gate drive power requirements and simplifying startup operations in flyback power supplies. Additionally, output capacitance has been reduced, resulting in a 30% decrease in Eoss, thereby reducing switching losses.

Achieving system-level improvements is not always straightforward, as design changes may require significant time and resources. In most existing low-power auxiliary power supply designs, Wolfspeed's new series of 900 mΩ silicon carbide MOSFETs offer plug-and-play compatibility, enabling you to fully leverage the benefits of the new devices without extensive redesign efforts. From a packaging perspective, the TO-247-3 (through-hole package) and TO-263-7 (surface-mount package) are compatible with other silicon carbide and silicon devices currently available on the market, eliminating the need to modify PCB layouts or heat sink attachments.

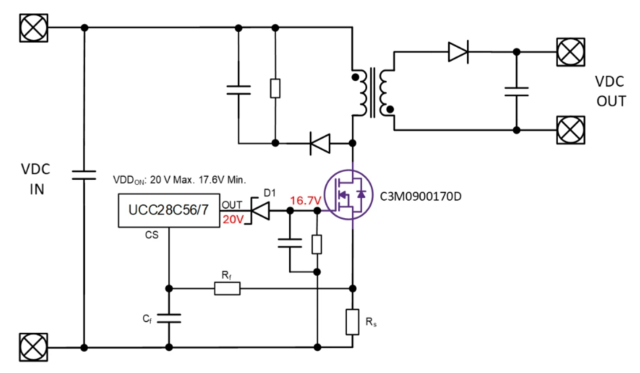

Many auxiliary power supplies feature a 12–15 V output for operating other controls or loads. The C3M/E3M series can directly utilise this voltage rail for flyback controllers and the resulting gate voltage, eliminating the need for separate auxiliary windings or transformer taps, and providing the higher 18–20 V voltage required by previous generations and certain competitors.

The gate voltage levels of silicon and silicon carbide MOSFET competitors range from 12 V to 20 V, complicating designers' challenges in multi-source designs. Fortunately, the Wolfspeed C3M0900170x series directly supports 12–18 VGS. Thanks to optimised internal gate resistances, Wolfspeed devices can operate under circuit conditions up to 22 VGS. In designs with gate voltages > 18 V, a Zener diode can replace the external gate resistor to reduce the drive voltage to within the 12–18 V range.

Replace RG_EXT with a 3.3 V Zener diode to reduce VGS at the MOSFET gate

Performance improvements when upgrading silicon-based systems

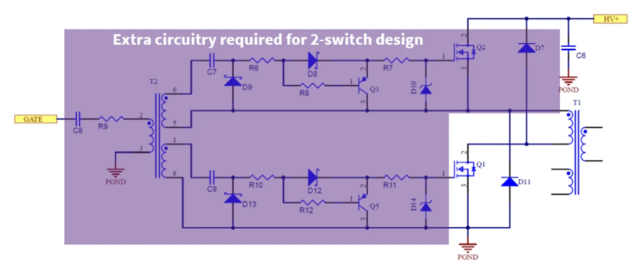

Although high-voltage (1500–2000 V) silicon MOSFETs can also be used in this system space, the drawback is that devices with 1–2 Ω RDS(ON) per unit area are often more expensive and have higher losses. Instead, a dual-switch flyback topology can be used to select lower-voltage silicon devices. While such devices are cheaper, the dual-switch topology design is more complex and requires additional components and space.

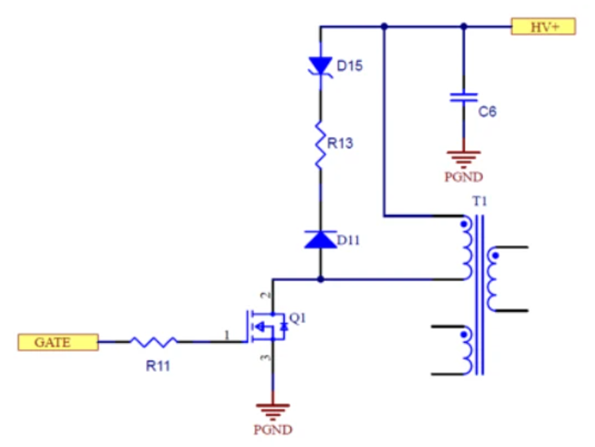

Silicon carbide MOSFETs are well-suited for this voltage range and can easily achieve low RDS(ON) and low switching losses suitable for auxiliary power applications. Designers can utilise a single-switch flyback topology, which eliminates the additional circuitry and design complexity required by the dual-switch design.

The dual-switch topology requires additional components and extra PCB area

The simplified single-switch design using silicon carbide MOSFETs saves space and cost.

Durability design for all applications

Auxiliary power supplies are commonly found in industrial and automotive applications requiring long lifespan and reliable operation. The C3M/E3M series is rated for operating junction temperatures from -55 °C to +175 °C, making it suitable for extreme temperature conditions. The C3M0900170D, C3M0900170J, and E3M0900170D have all passed the THB-80 (HV-H3TRB) test, which involves applying a 1360 V blocking voltage under conditions of 85% humidity and an ambient temperature of 85 °C for a continuous 1000-hour test.

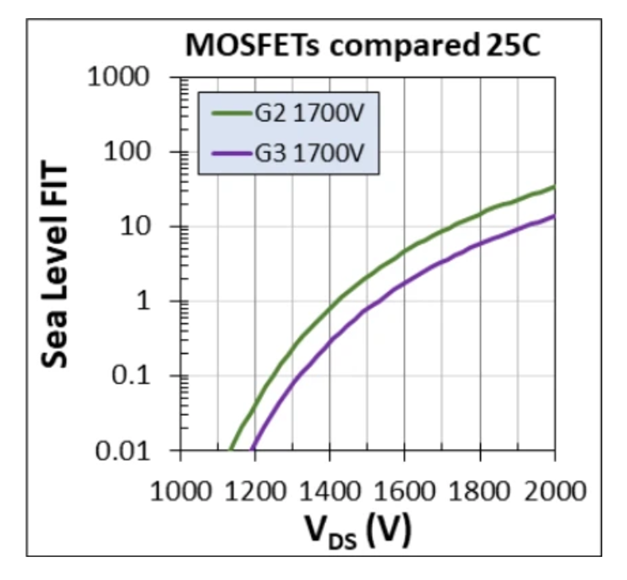

When discussing the reliability of semiconductors in various applications, it is essential to consider the failure rate (FIT) caused by cosmic radiation. The Wolfspeed C3M/E3M series further reduces the already low failure rate (FIT) of the previous C2M series through improved device design and reduced chip size. Compared to the previous generation, a typical 1200 V bus voltage flyback circuit using Wolfspeed's third-generation devices achieves a 65% reduction in failure rate (FIT) after continuous operation at sea level for 10 years.

Design resources for initiating silicon carbide system development

Wolfspeed leads the industry in providing design support to engineers, and the newly launched 1700 V series components are no exception. Review the resources below to accelerate your design using this new C3M/E3M series 900 mΩ 1700 V device.

Time:2025-08-16

Time:2025-08-16

Time:2025-08-16

Time:2025-08-16

Contact Number:86-755-83294757

Enterprise QQ:1668527835/ 2850151598/ 2850151584/ 2850151585

Business Hours:9:00-18:00

E-mail:sales@hkmjd.com

Company Address:Room1239, Guoli building, Zhenzhong Road, Futian District, Shenzhen, Guangdong

CopyRight ©2022 Copyright belongs to Mingjiada Yue ICP Bei No. 05062024-12

Official QR Code

Links: